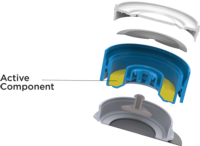

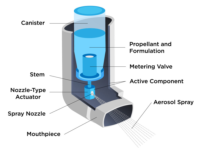

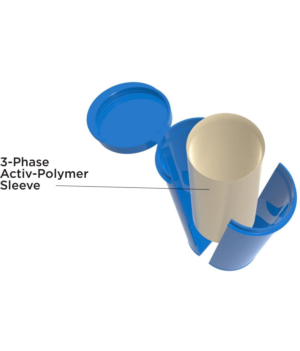

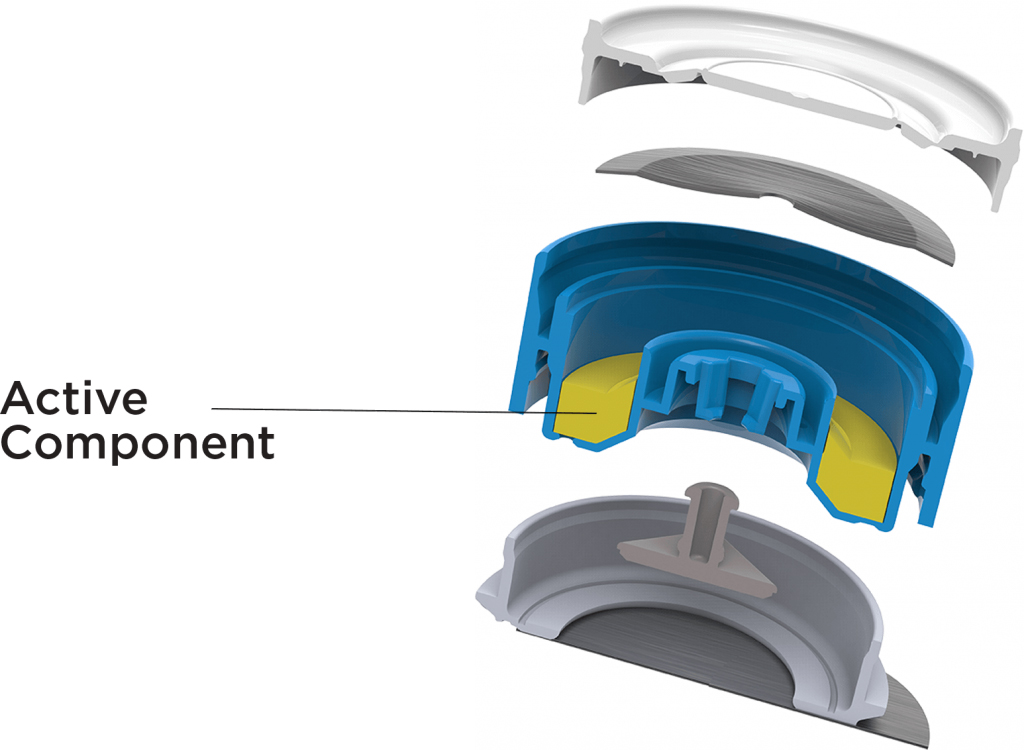

Activated device components using our 3-Phase Activ-Polymer™ technology provide structure and protection simultaneously.

3-Phase Activ-Polymer™ Activated Components

Active Protection

Improved Product Performance, Superior Product Protection, Greater Design Flexibility

Superior product protection

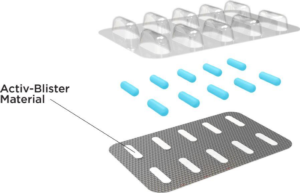

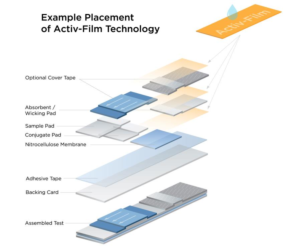

With our activated components, your products will benefit from superior protection. The components are designed to be seamlessly integrated into a device or package, often replacing an existing plastic part with an active component that controls the headspace environment. The result is maintained function while incorporating the performance of the 3-Phase Activ-Polymer™ technology.

Reduced complexity and streamlined design

By integrating an activated component into your device or packaging design, we reduce assembly complexity by reducing the number of components needed. This solution also minimizes size by incorporating absorption capabilities into mechanical components, controlling moisture without the need for extra space or changes to your current packaging design.

Extend shelf life

Our custom designed activated components allow for integrated product protection for managing the environment surrounding your drug product, which ultimately results in extended shelf life.

Custom designed solutions

We will work with you from concept to commercialization, assuring that the activated component we design for your specific needs delivers superior product protection, enhancing your brand and driving customer loyalty. Activated components can be an integral component of a device or the container for active packaging. Active molded components often replace a current plastic part in the customer’s packaging or device. This solution provides the current plastic part’s physical functioning while incorporating the chemistry’s performance.

3-Phase Activ-Polymer™ Activated Component Advantages

Product Details

We work with our customers to define the best solution for their stability needs. Our 3-Phase Activ-Polymer™ technology can be integrated into a molded component for a device or a container. Often, molded components replace a current plastic part in the customer’s packaging or device, providing the current plastic part’s physical functioning while incorporating the desired chemistry’s performance.

Our solutions do not use environmentally damaging epoxies or polyurethane resins that can create chemical incompatibilities and complicate safe recycling. Our activated components create single-part solutions that release low/no particles and are compatible with traditional forms of sterilization (e.g. gamma radiation).

The compositions of Aptar CSP’s 3-Phase Activ-Polymer™ technology are designed to comply with the U.S. Food and Drug Administration (FDA) and the European Union (EU) Guidelines for Food and Drug Contact. 3-Phase Activ-Polymer™ technology formulations are described in our Master Drug File #14789.

Learn More About Custom-Designed Active Components

Active components can open a world of possibilities for solving your stability issues. Let us help you find the right solution for your stability challenge.