Pharmaceutical, Other routes

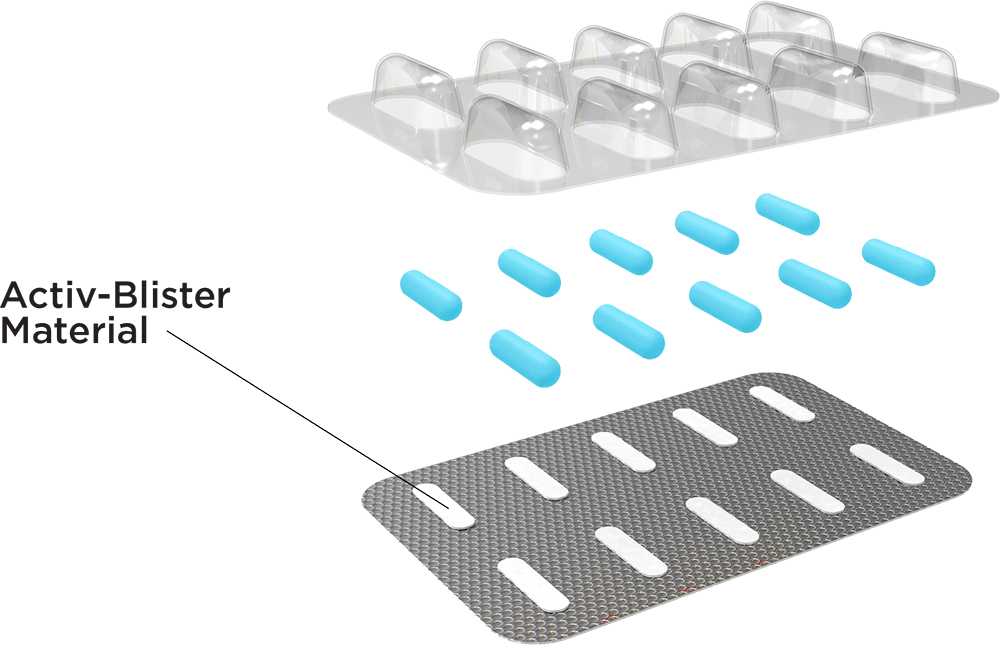

Activ-Blister™ Solutions

Active ProtectionAdvanced Protection for Sensitive Oral Solid Doses and Dry Powder Inhalation Capsules

Optimized for a wide range of formats

Activ-BlisterTM solutions can be incorporated into a wide range of blister packaging formats, designed around your project’s needs. Activ-Blister™ solutions can be produced in shapes and sizes to accommodate any tablet and capsule size, providing the protection your application needs in the blister package design your customers want.

Design flexibility

Blister packs have become the preferred and fastest-growing packaging options for the pharma industry. Products typically stored in bottles, with desiccant sachets, can use thermoformed blister cards without sacrificing headspace protection. With Activ-Blister™ Solutions, you can move from cold-form to thermoforms, offering your customer a visible oral solid dose product with a smaller blister footprint (40-60% smaller).

Enhanced performance, extended shelf-life, customer convenience

Activ-Blister™ technology controls the internal atmosphere of each individual blister cavity, protecting moisture and oxygen-sensitive oral solid doses and dry powder inhalation capsules.

This proprietary technology integrates a precise formulation to control humidity, oxygen and reactive impurities within the headspace of each blister, extending shelf life and improving stability.

The result is optimized product performance, extended shelf life, and greater consumer convenience.

Activ-Blister™ Advantages

Product Details

Product Details

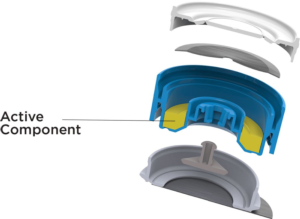

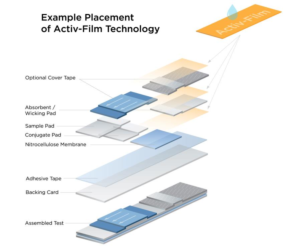

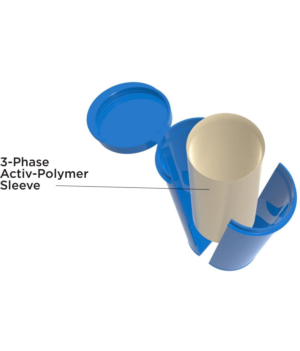

Our material science experts work with each customer to custom-design the precise formulation needed to assure their drug product is adequately protected. Activ-Blister™ solutions leverages the company’s patented 3-Phase Activ-Polymer™ technology to control moisture and oxygen kinetics based upon formulation, increasing or decreasing uptake rates and capacity.

Activ-Blister™ Solutions can be seamlessly integrated into new or existing packaging lines via the addition of a Film Applicator Module or FAM. The FAM runs inline and securely binds the Activ-Blister™ film to the lid stock using our proprietary heat-staking technology. Click here to learn more about our Rapid-Start Program that delivers Activ-Blister™ samples with your API inside in as little as four weeks.

Activ-Blister™ Solutions are integrated into current blister packaging lines using Aptar’s patented heat staking process. This means there is no use of adhesives, helping customers meet ICH guidelines for residual solvents.

Learn More About Activ-Blister™ Solutions

Learn how our innovative technology can address your stability challenges in ways you never imagined possible.