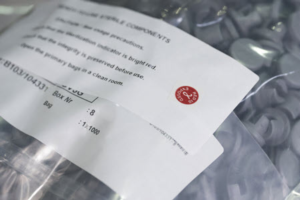

The PremiumCoat® platform of components and services combine a pure elastomer formulation, a state-of-the-art process and an ETFE film-coating technology to maintain the integrity of sensitive injectable drugs.

PremiumCoat® reduces extractables and leachables to improve the compatibility with the drug and accelerates drug-development programs while ensuring patient safety.

We are expanding our manufacturing capabilities worldwide to ensure your security of supply from drug development through to market launch.

We are shaping the future of injectables, together with our Pharma partners.