Ensuring that the drug remains sterile throughout fill-finish operations is crucial for delivering safe doses to patients. The recent revision to EMA GMP Annex 1 mandates that all sterile manufacturers adopt comprehensive sterility assurance strategies.

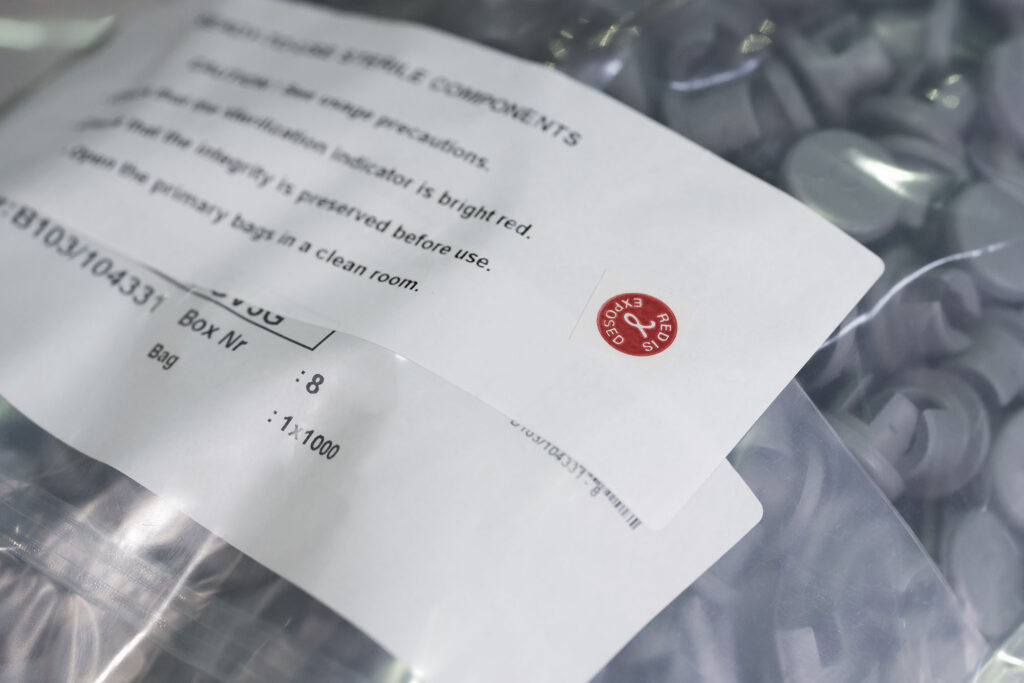

Aptar Pharma’s range of injectable components, including vial stoppers and syringe plungers, can be delivered in a Ready-to-Use (RTU), gamma sterilized format. Our unique processing and packaging methods allow us to guarantee 100% sterility at the time of use. Integrating gamma sterilized RTU components into your operations can enhance efficiency by eliminating the need for in-house sterilization procedures.