Particulate contamination and product cleanliness are primary concerns in the pharmaceutical market. The latest EMA GMP Annex 1 revision requires that pharmaceutical companies establish more stringent contamination control strategies (CCS) that encompass their operations and suppliers.

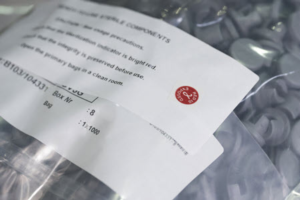

Aptar Pharma’s PremiumFill® solutions offer improved specifications regarding key contamination criteria as defined in Annex 1 such as particulates, biological or fiber contamination. PremiumFill® contribute to enhanced patient safety while promoting operational efficiency.