Pharmaceutical, Injectables

Rapid Transfer Port (RTP) Bags for Vial Stoppers and Syringe Plungers

Vial Containment Solutions & Syringe ComponentsIn today’s regulatory environment, patient safety is a priority, making contamination control and sterility essential in pharmaceutical manufacturing. The latest EMA GMP Annex 1 revision recommends isolators or Restricted Access Barrier Systems (RABS) on aseptic vial or syringe filling lines.

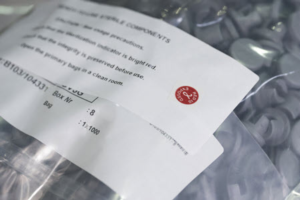

Aptar Pharma offers a range of vial stoppers and Pre-Filled Syringe (PFS) plungers in customizable Rapid Transfer Port (RTP) bags to support sterile, particulate-free aseptic fill finish operations.

Achieve Sterile, Contamination-Free Fill-Finish Operations with RTP Bags for Aseptic Transfer

Sterility & Contamination Control with RTP Bags

In today’s biopharmaceutical industry, maintaining strict aseptic processing is essential to preventing contamination. Aptar Pharma offers rubber components for injectables packaged in Rapid Transfer Port (RTP) bags from top suppliers of RABS or isolator port systems, ensuring aseptic transfer to today’s fill-finish lines. Our RTP bags connect seamlessly to isolators and RABS, eliminating direct human contact during the transfer of rubber components and reduce the risk of contamination during fill-finish operations.

Aptar Pharma’s Ready-To-Sterilize (RTS) and Ready-To-Use (RTU) gamma-sterilized products come in polyethylene or Tyvek RTP bags, tailored to your specific process needs for clean, compliant component transfers of vial stoppers and syringe plungers.

Setting the Standard in Aseptic Transfers

The 2022 revision of the EMA GMP Annex-1 regulations emphasize contamination control and sterility in aseptic processing. Sections 4.3 and 8.47 recommend the use of isolators or RABS to reduce microbial and particulate contamination risks. To support Annex-1 compliance, Aptar Pharma provides advanced parenteral closure components in Rapid Transfer Port (RTP) bags, enabling safe, aseptic transfer that can help to streamline the approval processes.

Next

Product Details

Aptar Pharma’s vial stoppers and pre-filled syringe (PFS) plungers are packaged in Rapid Transfer Port (RTP) bags for safe, aseptic transfer on fill-finish lines. Compatible with Restricted Access Barrier Systems (RABS) and isolators, these RTP bags help maintain sterility and reduce contamination risks.

Ready-To-Use (RTU) gamma-sterilized components come in polyethylene Rapid Transfer Port (RTP) bags, while Ready-To-Sterilize (RTS) components are packaged in Tyvek RTP bags for steam sterilization. All RTP bags are packed in Akylux® boxes to reduce particle generation, ensuring clean, contamination-controlled operations.

Learn more about Aptar Pharma's Ready-To-Use (RTU) gamma-sterilized components

Aptar Pharma provides a wide range of Rapid Transfer Port (RTP) bags, compatible with multiple isolator/RABS port brands and sizes to fit your pharmaceutical needs:

Getinge: Available in 105 mm and 190 mm sizes

Sartorius: Available in 110 mm size

Our RTP bags deliver secure, reliable aseptic component transfer solutions for contamination control, supporting optimal performance in aseptic pharmaceutical applications.

Aptar Pharma offers a versatile selection of Rapid Transfer Port (RTP) bags with features tailored to your specific requirements:

Port Protection: Choose rigid or peelable options to prevent contamination.

Sleeves: Available in different lengths and designs to ease component transfer.

Bag Sizes: Various sizes to suit your process needs.

Our RTP bags support enhanced contamination control and flexibility in virtually every operation.

Contact Aptar Pharma’s Parenteral Expert Team Today

Learn more about how we can support your compliance with Annex-1 revision requirements and optimize your operations with our Advanced Parenteral Packaging Solutions.

You Might Also Be Interested In These Products

Pre-filled Syringe Component Platform

Vial Containment Solutions & Syringe Components

Pharmaceutical

PremiumCoat® ETFE film-coated vial stoppers and syringe plungers

Vial Containment Solutions & Syringe Components

Pharmaceutical

PremiumFill® for Improved Particulate Specification

Vial Containment Solutions & Syringe Components

Pharmaceutical

Ready-To-Use, Gamma Sterilized Closure Components

Vial Containment Solutions & Syringe Components

Pharmaceutical

Vial Containment Solutions: Stoppers for Liquid and Lyophilized Drugs

Vial Containment Solutions & Syringe Components

Pharmaceutical