Pharmaceutical

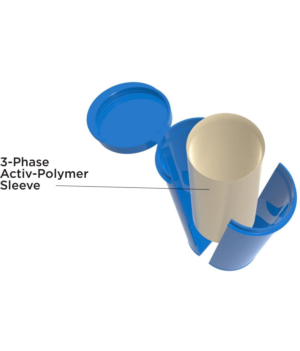

3-Phase Activ-Polymer™ Technology

Active ProtectionOur proprietary 3-Phase Activ-Polymer™ technology enables development of bespoke material science-based innovations and active packaging solutions providing ultimate protection against moisture, oxygen, and VOCs.

Our solutions provide premier product protection for sensitive drug products, probiotics, medical devices, drug delivery systems, and even foods.

Highly Engineered Material Science and Active Packaging Solutions Protect Product Integrity

Customized material science and active packaging solutions

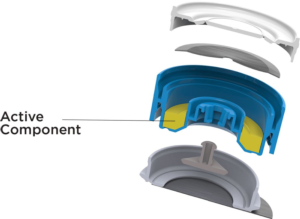

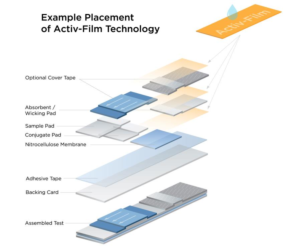

Our 3-Phase Activ-Polymer™ platform technology offers customized material science and active packaging solutions designed to meet the protective needs of drug developers’ specific formulations. The technology incorporates active chemistries to provide moisture control, gas scavenging (Oxygen, CO2, Ethylene, Formaldehyde, etc.), microbial pathogen reduction, and aroma reduction or emission.

Expanded drug delivery options

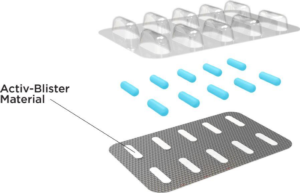

We utilize our active material science expertise to bring sensitive and complex formulations to market, enabling seamless integration of oxygen scavenging and moisture adsorption solutions into any device or packaging configuration. Move from bottles to blisters or incorporate a molded active component to enhance stability without impacting your product’s device or packaging design.

Extend shelf life

3-Phase Activ-Polymer™ technology allows for integrated product protection for managing humidity, oxygen, and VOCs without gas flush/purging, secondary packaging, or refrigeration.

Proven expertise

With more than 20 years of expertise in material science, Aptar CSP’s 3-Phase Activ-Polymer™ technology is utilized by leading global brands with a wide range of products to extend shelf life, maintain freshness, and improve efficacy in industries such as pharmaceuticals, medical devices, and food safety.

3-Phase Activ-Polymer™ Technology Advantages

Product Details

Utilizing 3-Phase Activ-Polymer™ technology requires a tightly sealed environment. The amount of 3-phase material required to manage the environment around the drug product depends on how tight of an environment it will be placed in. When you marry the tightly sealed environment or package with the proper amount of 3-Phase Activ-Polymer™ technology, you have a total system solution to protect your sensitive products.

3-Phase Activ-Polymer™ technology is uniquely adaptable. Commercial applications include injection molding, thermoforming, extrusion film, extrusion blow molding and hot melt. This flexibility makes the technology applicable across the spectrum of the pharmaceutical industry.

Because the format of 3-Phase Activ-Polymer™ technology is so flexible, it can be leveraged in a broad range of fields. This technology can be specially designed to protect oral solid doses, medical devices, probiotics, inhalation, diagnostics, dermal drug delivery and more. It is even used in the food industry to protect against pathogens and maintain food freshness and quality.

Learn More About 3-Phase Activ-Polymer™ Technology

Let us help you think outside the box and determine how our technology can help protect your important products.