At Aptar Pharma, we understand the importance of supporting our Pharma partners as you choose and validate your injectable packaging components. We can support you in many different ways such as providing data packages and/or analytical services, which can help you get to market faster with less risk.

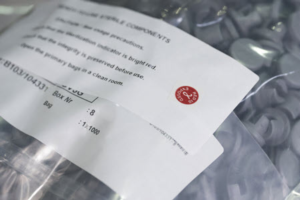

PremiumCoat® Data Packages provide you with all the information, test data and analysis you will need to understand our solution’s performance and help you make a fact-based decision when choosing PremiumCoat®. These data packages include glass container compatibility data (such as Container Closure Integrity Testing, pop-off testing), simulation studies to help anticipate potential issues linked to leachables, and the full extractable file for your regulatory submission.

PremiumCoat® Service Packages leverage the capabilities of our Aptar Pharma Service Companies, providing end-to-end support for your drug development process and validating your choice of primary packaging for your drug.

We also offer a wide range of analytical testing services to support your specific development needs:

Although our solutions are designed to be versatile, we understand that each project may require a tailor-made approach. That is why we offer customized syringe components and services to meet the unique needs of your project. Our experts are ready to support you in evaluating your requirements and designing the pre-filled syringe plunger stoppers and rigid needle shield and other syringe components, that you need for the success of your drug.